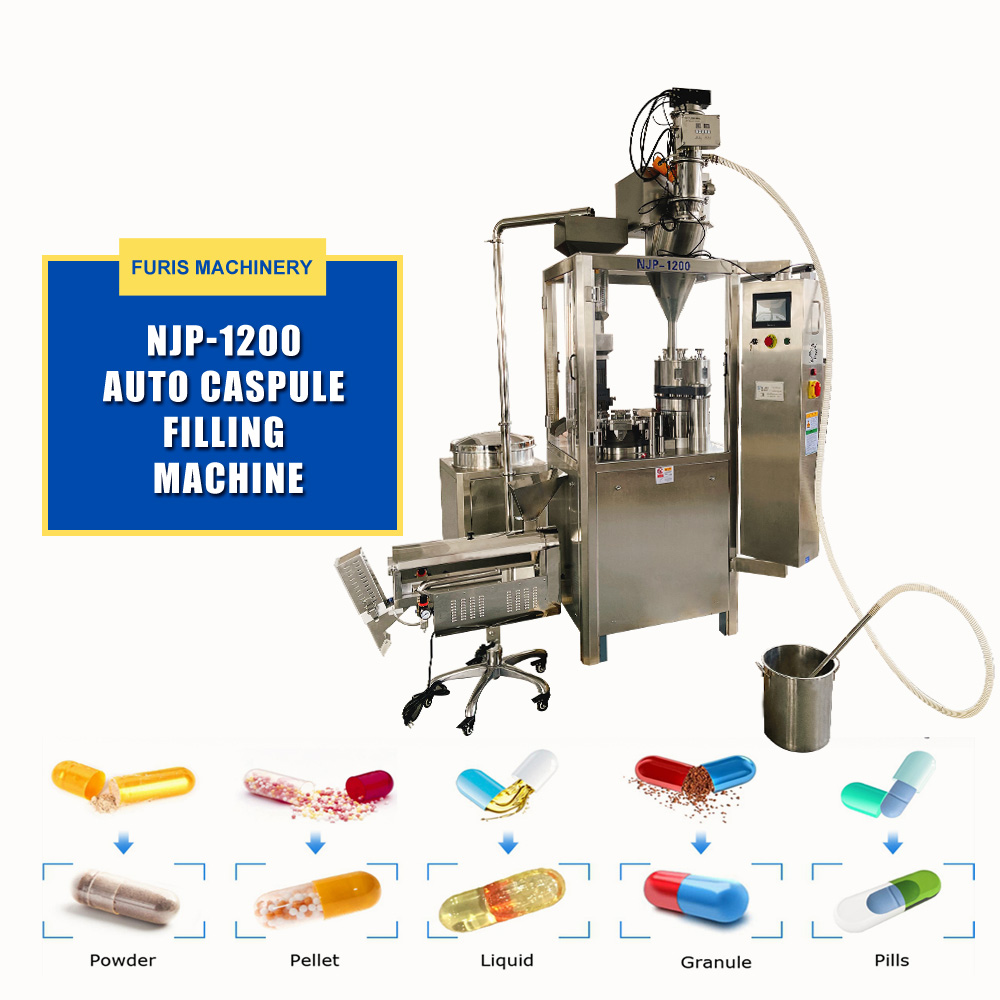

Furis machinery group is a integrated the machine research and sales enterprise.We are a professional manufacturer for making pharma packing machine and cosmetic personal care products machine,etc.Our main product :capsule tablet blister packing machine,capsule filling machine,capsule counting machine,tablet bath bomb press and packing line,detergent capsule pod making machine,etc.

Read more

We own a modern standard factory of over 10,000 square meters with 80 skillful workers. Our production is organized strictly according to the ISO9001:2002 quality management system, and our machines have obtained the CE certification. We utilize advanced equipment, high manufacturing technology, and a perfect inspection system to ensure product quality and precision. With complete production equipment, stable quality, reliable performance, and good after-sales service, our products are becoming increasingly popular in the international market.

SEND YOUR INQUIRY DIRECTLY TO US