DPP-260 Full Automatic Mini Tablet Blister Packing Machine PVC ALU Medical Packaging Food

Applying:

It is suitable for capsule, tablet, honey pill, candy, liquid (ointment), paste as well as irregular shape Al-al Al-plastic and paper-plastic composite sealing packing in pharmacy, healthcare, food, cosmetics, medical equipment industry etc.

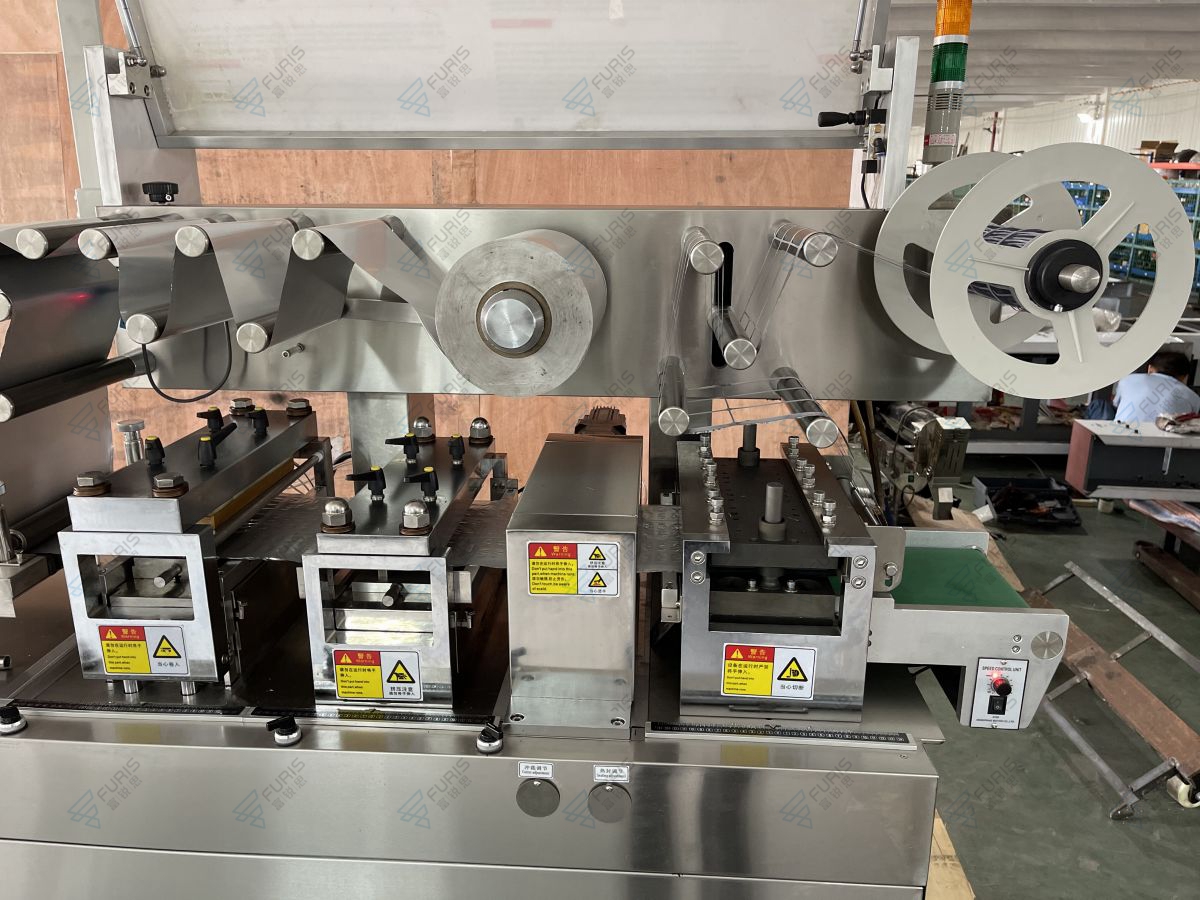

Features:

1. The whole structure adopts open layout structure, and the modular design has good station visibility and convenient maintenance and adjustment. Novel and safe appearance protection design is for safe operation.

2. With the heating plate temperature control, the main motor overload protection, PVC and PTP package material position detection, feeding storage position detection control, automatic protection shutdown if have fault.

3. The heating mechanism adopts the contact type version of the heating, the delay of the turning-on after the heating plate is put down, will limit the material waste in a stroke within; and reduce the heating power and heating temperature, save energy and enhance the stability of the plastic film, not easy to deformation.

4. Increase PVC rapid replacement material feeding platform, rapid material platform, whole guide, increase the overall practicality of equipment.

5. Molds concave groove positioning, rectangular design, positive pressure forming, micro edge blanking, replacement more convenient and quick. All parts of contact with drugs are made of high quality stainless steel and high quality aluminum alloy non-toxic materials, high-grade surface treatment process, texture emerging.

6. Cushion seal: when the machine stops, the cylinder will automatically rise the netted plate.The deformation of the bubble caused by heat radiation during the stay is eliminated, which is convenient for the cleaning of the netted plate, and the buffering effect of the super pressure is also beneficial to prolong the service life of the machine.

7. The upper and lower netted plate is heat sealed work in with each other: that is, both the positive and negative sides are dot like recalculate (also can be linear sealed), because the stress is equal, the plate is more smooth, and the sealing performance is improved.

8. Adding a separate batch number embossing position, abandon the disadvantages of the difficult to handle or manage when change molds in the sealing position, and the design of batch heating mechanism, ensure the clarity of printing.

9. The printing register control system can be used to the register to the pictures and the words on the printed aluminum foil.

10. Frame type filling is efficient and reliable. It can be adapted to various typesetting methods and filling of irregular shapes. (according to the packing products design mating special feeder)

11. Using high-end PLC control, touch screen operation, digital display in English and Chinese, frequency conversion speed regulation, servo traction, traction length in the traction size range can do arbitrary adjustment on the touch screen.

12. The finished products are orderly output, the defective products are collected easily, and equipped with waste collection device, and the waste is collected easily.

13. The whole machine is designed by split connection, which is easy to enter the elevator and workshop.

14. Easy change the mold,just need 5mins can finish it.

Parameters

| Model | DPB-260 | |

| Blanking frequency(standard) | 20-60times/min(alu plastic)15-30times/min(alu alu) | |

| Max. forming area and depth | 250X110X15(alu plastic) 250X110X12(alu alu) | |

| Range of travel | 30-120 | |

| Packaging material Φ75 |

PVC | (0.15~0.4)X 270X(Φ400) ㎜ |

| PTP | (0.02~0.15)X 270 X(Φ300)㎜ | |

| ALU ALU FOIL | (0.16-0.2)X 270 X(Φ400)㎜ | |

| Paper | (50-100)g/㎡X270X(Φ300) ㎜ | |

| Power | 380V 50Hz 8kw | |

| Air compressor | ≥0.25m³/min 0.6~0.8Mpa | |

| Mould cooling | 60-100L/h | |

| Dimension(L X W X H) | 3550 X 900 X 1900 | |

| Weight | 2T | |

2

2

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

Furis I/E company is a sub-company of furis group,it is especially for importing and exporting. Furis group is a integrated the machine research and sales enterprise.We are a professional manufacturer for making pharma machine and personal care products machine,etc.Our main product :blister packing machine,capsule filling machine,tablet press machine,bath bomb making packing line,detergent pod making line,face mask machine,shoe cover machine,bouffant cap making machine,labeling machine,etc We own more than 10000 square meter modern standard factory,has 80 skillful workers.We strictly according to ISO9001:2002 quality management system to organize producing,the machines gets the CE certification.The advanced equipment, high manufacture technology and prefect inspection system assures products quality and precision.With complete production equipment,stable quality,reliable performance and good after service. Our products are more and more popular in the international market. "Growing with clients" is always our management concept. We believe truthfulness, conscientiousness, enterprising spirit, continuous improvement and creativeness in running business, Welcome the oversea customer cooperate with us. Please feel free to contact us for more details.

FAQ

1. who are we?

We are based in Zhejiang, China, start from 2012,sell to North America(00.00%),Western Europe(00.00%),South America(00.00%),Eastern Europe(00.00%),Southeast Asia(00.00%),Mid East(00.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

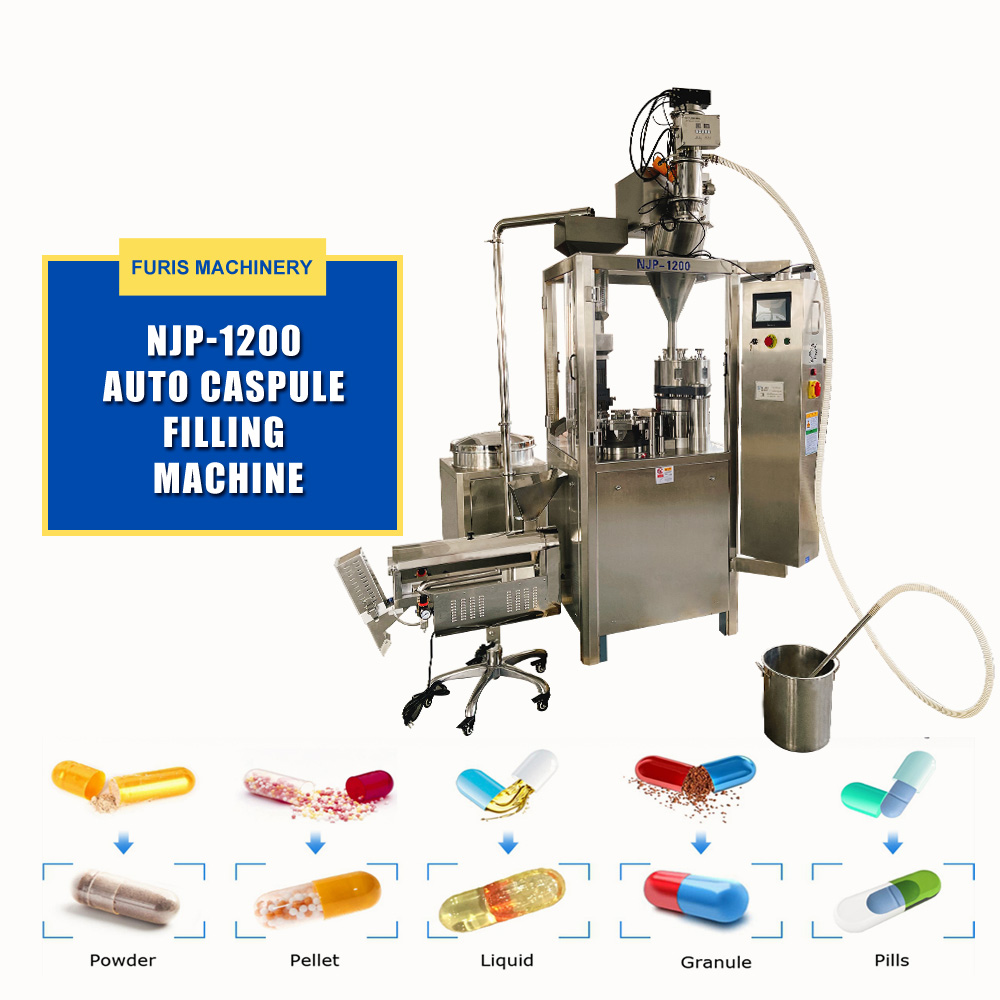

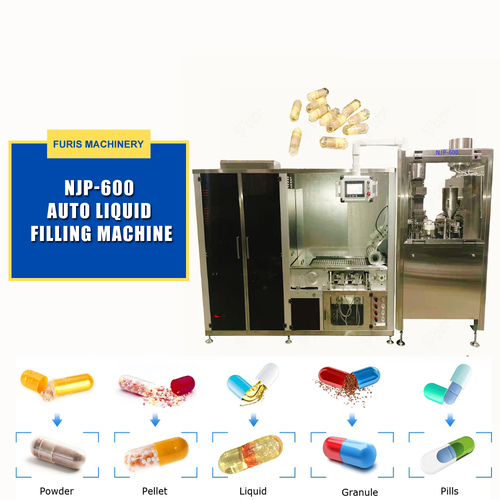

3.what can you buy from us?

Pharma Machine,Personal Care Product Machine,Capsule Filling Machine,Tablet Bath Bomb Machine,Face Mask Machine

4. why should you buy from us not from other suppliers?

More than 15 years experience in making pharma machine Pharma Machine one stop technician service In time technician support in the customer's country Professional Turnkey Project Economical Solution

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,HKD;

Accepted Payment Type: T/T,L/C,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese

description2

Send Email

Send Email whatsapp

whatsapp