0102030405

Improve efficiency and quality with film packaging machines

2023-11-07

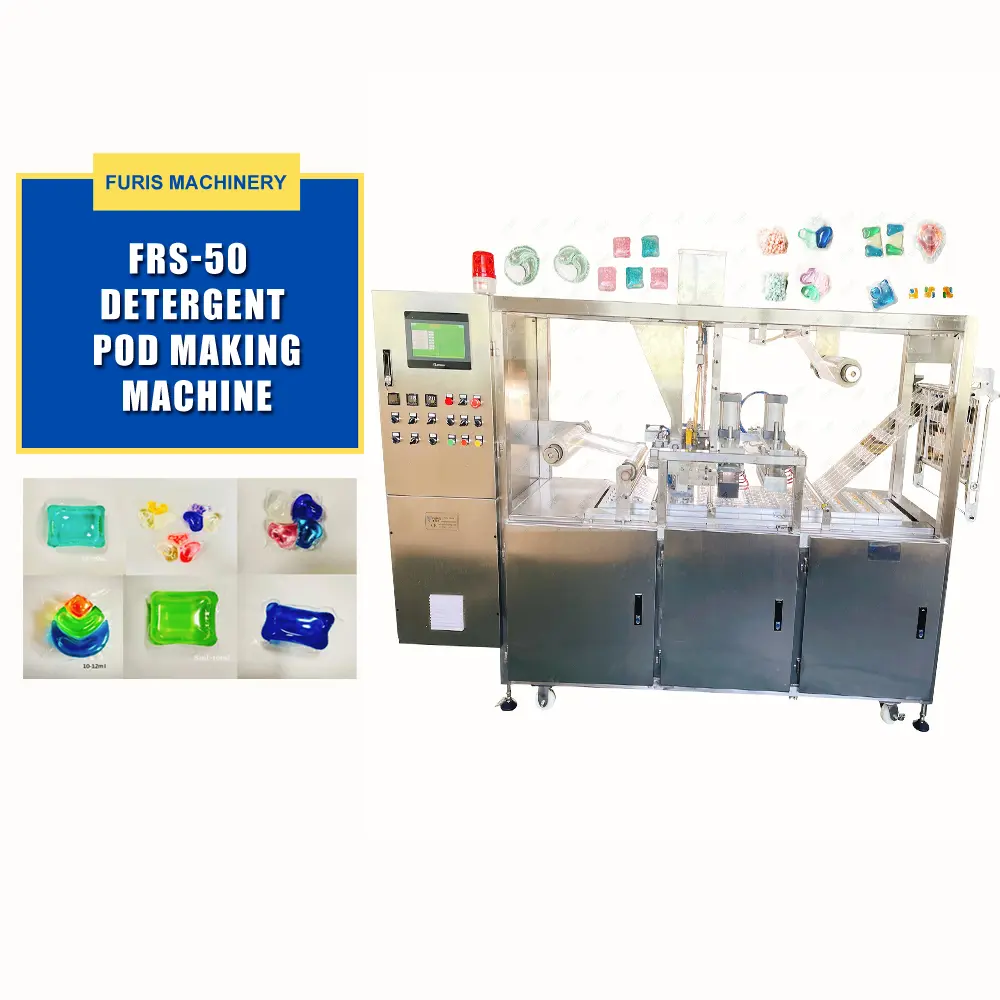

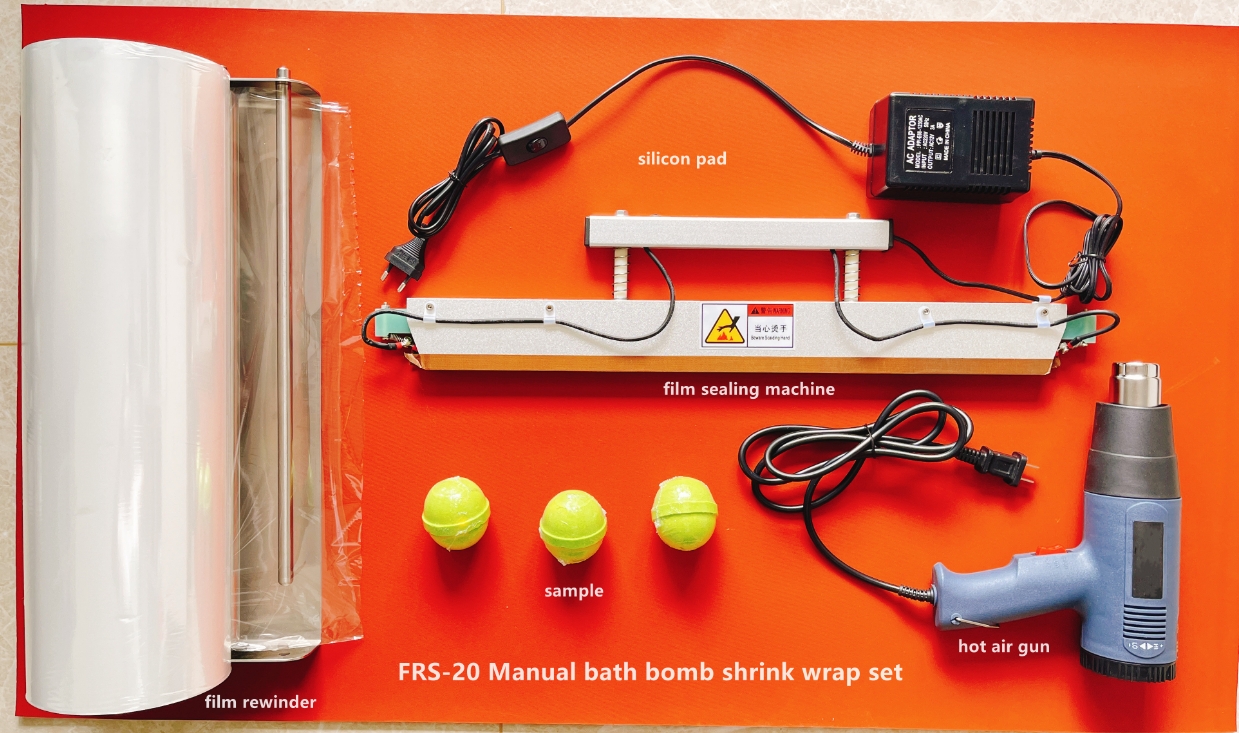

In today's fast-paced world, efficient and reliable product packaging plays a vital role in meeting customer expectations. As businesses strive to deliver products safely and efficiently, film packaging machines have become industry game-changers. Capable of handling a variety of packaging materials and adhering to specific storage conditions, this advanced machinery is revolutionizing the packaging process. In this blog, we will explore the advantages of film packaging machines and the importance of adhering to recommended storage conditions for packaging materials and semi-finished products. Film packaging machines are precision and innovatively designed to streamline the packaging process. It provides versatility in handling packaging materials, allowing businesses to meet customer-specified shape and weight requirements. With this machine, everything from fragile items to heavy-duty products can be packed seamlessly, ensuring maximum protection and preservation. The machine's automated capabilities speed packaging, speed turnarounds and increase productivity, allowing businesses to meet customer needs in a timely manner. To ensure the longevity and quality of packaging materials, they must be stored under recommended conditions. For water-soluble film packaging materials, maintaining a temperature of +15 to +30°C is crucial. Additionally, a humidity range of 30% to 45% should be maintained to prevent any condensation. Storage guidelines provided by the film manufacturer must be followed to maintain the integrity and performance of the packaging material. By following these recommendations, businesses can achieve better results and avoid any potential damage or deterioration of materials. Just like packaging materials, semi-finished products also require suitable storage conditions to maintain their quality. The recommended temperature range for storing such products is +15 to +30°C, and the humidity should be maintained between 30% and 55%. These conditions ensure that the semi-finished product remains intact without any damage caused by extreme temperatures or high humidity. By creating an optimized storage environment, companies can ensure efficient utilization of semi-finished products and a longer shelf life, thereby increasing overall productivity. Investing in a film packaging machine can bring many advantages to your business. First, it significantly reduces packaging time, resulting in faster order fulfillment and increased customer satisfaction. The machine's automated features minimize the risk of human error, ensuring packaging results are consistent and accurate. Additionally, the machine’s compatibility with a variety of packaging materials provides flexibility, allowing businesses to meet the needs of a variety of product types. Ultimately, film packaging machines increase efficiency, reduce costs, and improve the overall quality of the packaging process. Film packaging machines have become an indispensable tool for enterprises to pursue efficiency, quality and customer satisfaction in the packaging process. By adhering to recommended storage conditions for packaging materials and semi-finished products, companies can ensure the longevity and performance of these essential elements. With film packaging machines at the helm, companies can streamline operations, increase productivity, and effectively meet the changing needs of the market. Adopting this advanced technology is a step towards enhancing the overall packaging experience and achieving success in a competitive business environment.

Send Email

Send Email whatsapp

whatsapp